“Sumy NPO” PJSC plans to complete the painting of tanks for the needs of the German company Ingenieurbüro R. Großmann GmbH & Co. KG. KG. until the end of the current week.

“Sumy NPO” PJSC plans to complete the painting of tanks for the needs of the German company Ingenieurbüro R. Großmann GmbH & Co. KG. KG. until the end of the current week.

“This equipment should serve at least 30 years, so the requirements for its reliability and directly to the quality of the coating are very high. In particular, we provide a layer at the level of 300 microns, ” explained Sergei Grebenik, the head of workshop number 8, where these tanks are manufactured.

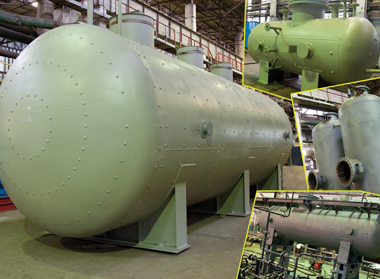

He recalled that the division assigned production of eight units of equipment, which as a whole form five process complicated tanks units for the future gas drying unit: emergency drainage, reflux, storage of raw triethylene glycol, degasser, as well as purifying blocks consisting of coal and cartridge filters.

Painting work started in the workshop number 8 in November. The emergency-drainage tank which is the largest among those specified in contract with German partners, had been prepared for shipment by the beginning of December. This is a horizontal apparatus for underground use with a volume of 70 m3; its length is over 8 m, and its diameter is 3 m.

The reflux tank was the next in painting process, and alternately, the coating is applied to all other samples of the above products. A considerable amount of work is also associated with the painting of various sections of the fence and maintenance sites, which in the framework of this project is plentiful.